On this page

Why log grades are used

Log grades are used to describe the quality of logs. They indicate which products could be made from the logs. Log buyers (for example, wood processors) usually need logs of a certain quality and size to make specific products.

Log specifications are chosen on which logs achieve the highest return, or on market conditions. They provide assurance to wood processors that the logs will meet their needs. Log grades and specifications are an important part of contracts between:

- suppliers, which includes forest growers

- log traders or wood processors.

The log specifications for each grade are given to harvest contractors. First the trees are felled, extracted to the processing area and trimmed of branches. Log makers then assess and grade the tree stems based the specifications supplied to them, and actual log quality. Finally, log makers cut the logs.

Logs are graded based on:

- whether they have knots

- the size of knots

- minimum diameter

- cut length

- other wood quality attributes, such as stiffness, straightness and defects.

Logs are assessed at harvest time to find out what the wood quality attributes are, which we talk about further down this page.

A tree will produce logs of different grades. This is because of differences in wood quality and timber characteristics as diameter reduces, branch size changes, and age of wood reduces along the stem. It can also be due to the silviculture regimes that were used.

New Zealand’s forestry and wood processing industry uses a broad range of log grades. Several names can be applied to a single log grade, which can be confusing. There are many bespoke grades or local variations. Different log grades are used for domestic and export markets.

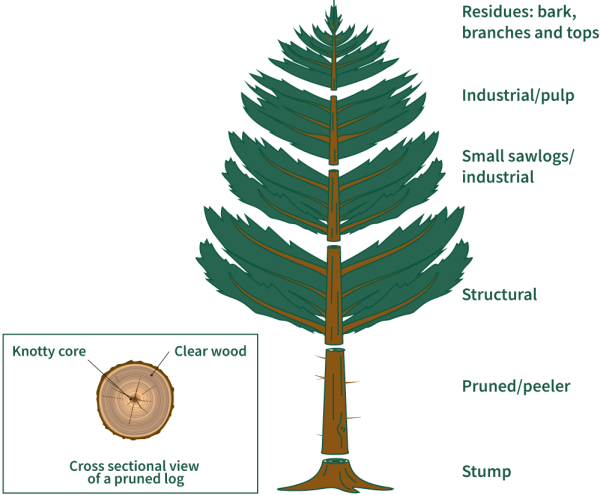

Figure 1: A diagram showing log grades in relation to the position up the stem. Pruning (removing branches) allows knot-free timber (known as clearwood) to form around the knotty core (see inset). Note: Section lengths are intended as a general guide and do not indicate the exact length of graded logs, which can vary.

Long description of this image – show/hide

This is a diagram of a pine tree with 6 sections. The section at the base of the tree is a short tree stump and is labelled 'stump'. The next section is about 3 times the height of the stump and shows a tree stem labelled 'pruned/peeler'. The remaining sections of the tree have branches and green needles. The next section is a slightly shorter section labelled 'structural'. Next is a section labelled 'small sawlogs/industrial'. The next section is the same height as 'small sawlogs/industrial' but slightly narrower, following the taper of a pine tree. It is labelled 'industrial/pulp'. The top section shows the tip of the tree and is labelled 'residues: bark, branches and tops'.

An inset to the left of the tree is a diagram labelled 'cross-sectional view of a pruned log'. It shows a cross-section of a tree stem with outer bark and inner growth rings. The centre is labelled 'knotty core' and the growth rings are labelled 'clearwood'.

Types of logs: their uses and grades

Different grades of log have different end uses. The highest grades are valued for their appearance or strength. Any section of a tree's stem can end up being used for industrial or pulp purposes, or as residues, if the wood is low quality or they have large branches.

Pruned (clearwood) logs or appearance quality logs

These are logs without knots, which is achieved through pruning. Pruning removes the lower branches of trees. These straight logs with large diameters are used to produce clear and appearance-grade lumber that is used for interior finishings, furniture, panelling, and mouldings.

Peeler logs

Peeler logs can be pruned and unpruned logs. The logs must have a large diameter and be round and straight, with the pith (the central core of a stem/log) exactly in the centre of the log. Unpruned peelers can have knots of up to 6 cm in size. Peeler logs are used for manufacturing plywood and veneers, including decorative overlay veneers.

Structural logs

Structural logs have high levels of stiffness (a measure of fibre strength) and stability (the degree to which wood swells and shrinks with changing moisture content). Small knots of up to 6 or 7 cm in size are acceptable. These logs produce timber used in buildings for framing, trusses, beams, and columns. Timber that is not fit for use in building can be used for fencing, decking, and other landscaping products.

Utility logs

Utility grade logs have larger knots (up to 10 to 12 cm in size) and defects than structural logs. These logs produce timber used to make pallets, orchard bins and crates for machinery, and cable drums. Utility logs can be processed into sawn timber after removing the knots. The clear timber components are then finger-jointed to produce a range of products including mouldings, weatherboards, fascia, boards, panelling, dowel, and jambs.

Industrial logs

Industrial grade logs are unpruned logs that are not suitable for structural uses. They are used to make concrete formwork, pallets, and cable drums.

They are also used to make various types of fibreboards and panels including particle board, medium density fibre (MDF) board, oriented strand board (OSB), and plywood.

Roundwood logs

These are logs with the smallest amount of taper, which is the degree to which a tree's stem or bole (trunk) decreases in diameter over a length. These logs are usually unpruned and of small to medium diameter. They must be chemically treated to extend their lifespan. Roundwood logs are often used for treated fence posts and strainers, retaining walls and landscaping, electricity transmission poles, and marine poles.

Pulp and chip logs

Usable logs that do not fit into any of the above categories are used to make pulp. This can be turned into paper, cardboard and packaging materials, wood chips, used as furnish for fibre boards and panels including MDF and OSB, or used for bioenergy.

Log specifications

Log classification in New Zealand often uses a prefix letter and a minimum small end diameter (SED). For example, ‘P40’ means pruned logs with a minimum small end diameter of 40 cm. Lower quality K grade logs use only one letter (see table).

Dimensional characteristics of logs

Log dimensions are specified in terms of length and diameter. Both are specified with a tolerance allowing for manufacturing variability. Log length and diameter affect the volume and desirability of the log, and therefore the market price of the log.

Diameter

Small-end diameter (SED) is specified in terms of minimum, maximum, average and method of measurement. Large-end diameter (LED) is usually a measurement of the log’s widest point.

Length

The specified length of a log includes some trim allowance on either side of the log. For example, a 5 m log may be longer than 5 m before processing, but will be 5 m once it is squared up. This ensures customers recover the required length after processing. Some processors expect a certain length of recoverable material in the trim.